Save up to $600*

during our rebate event

*while purchasing up to three eligible models

Enhance your curb appeal with our Garage Doors

Clopay® has a commercial door for virtually any application

Browse Doors

Rolling Doors

Clopay’s rolling service and garage doors provide efficiency and flexibility for interior and exterior use.

Sectional Doors

Clopay’s commercial-graded sectional doors meet the day-day needs of virtually any business application.

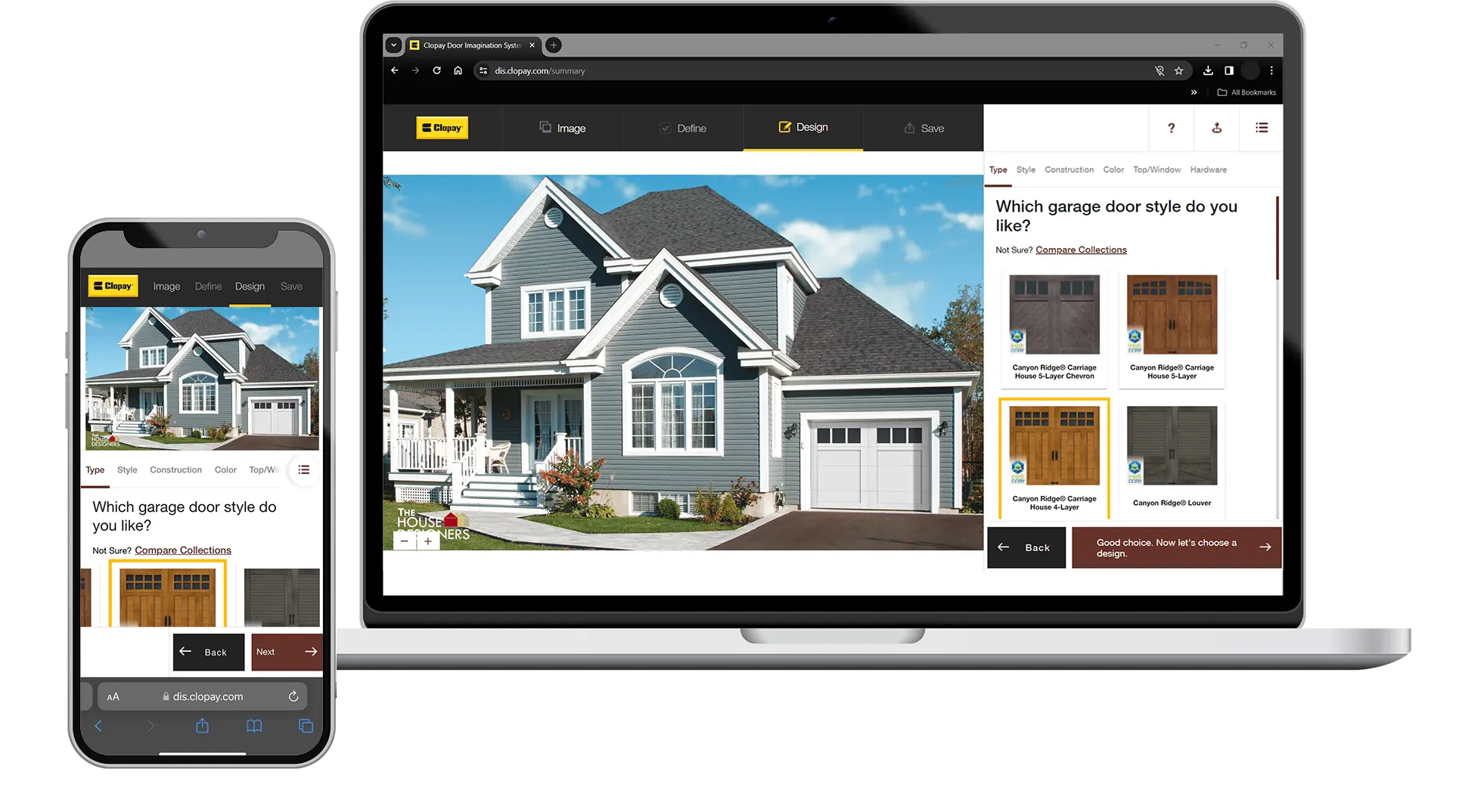

Design & Build Your Own Door

Try on garage doors with Clopay's Door Imagination System

Start Customizing Now

FREE Color Samples

Order up to THREE samples delivered straight to your door, at no cost!

Don't let online or indoor variations deceive you. Try before you buy and get your color samples today!

Find Inspiration With Clopay's® Lookbook

Projects from award-winning architects, builders and influencers featuring garage doors from Clopay

Experience Lookbook